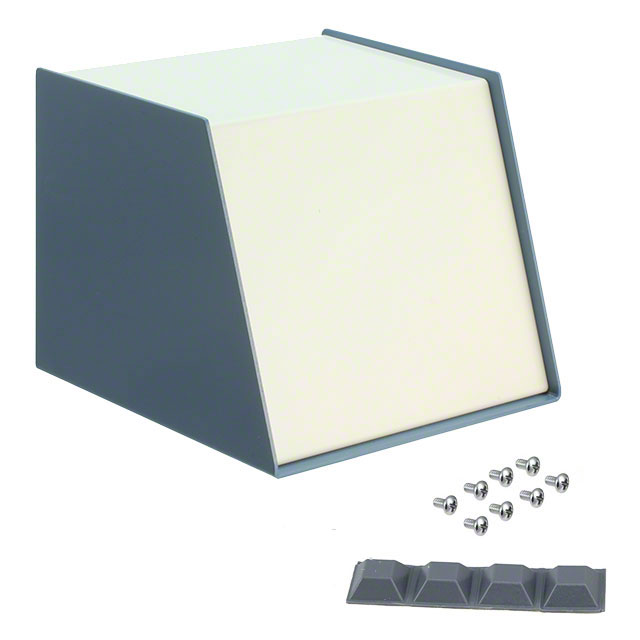

| Part number: | UNC 5-6-6-BLUE/WHITE |

|---|---|

| Product classification: | Boxes |

| Manufacturer: | LMB Heeger, Inc. |

| description: | CABINET ALUM BL |

| Encapsulation: | - |

| Packing: | Bulk |

| Quantity: | 1 |

| RoHS: | 1 |

Quantity

Price

Total price

1

$76.8720

$76.8720

10

$67.2600

$672.6000

100

$63.9000

$6,390.0000

| TYPE | DESCRIPTION |

| Mfr | LMB Heeger, Inc. |

| Series | Uni-Cab |

| Package | Bulk |

| Product Status | ACTIVE |

| Features | Separate Panel or Cover Thickness |

| Color | Blue, White |

| Size / Dimension | 6.000" L x 6.000" W (152.40mm x 152.40mm) |

| Material | Metal, Aluminum |

| Thickness | 0.090" (2.29mm) |

| Shipping Info | Shipped from Digi-Key |

| Height | 5.000" (127.00mm) |

| Design | Slanted Top |

| Container Type | Cabinet |

| Area (L x W) | 36.0in² (232cm²) |